Complete Guide to Composite Testing and Validation for Modern Manufacturing

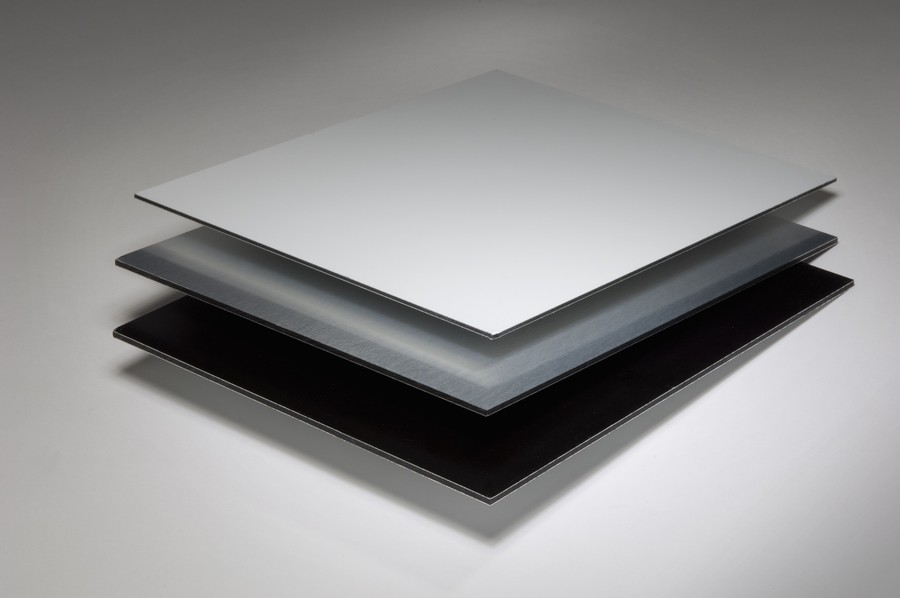

Composite materials—such as carbon-fiber reinforced polymers, glass-fiber laminates, and advanced thermoset resins—have revolutionized sectors like aerospace, automotive, renewable energy, and marine engineering. Their combination of light weight, high tensile strength, and corrosion resistance allows engineers to design stronger yet lighter components that outperform traditional metals.

However, these advantages depend entirely on the quality and consistency of the composite itself. A single weak layer or manufacturing defect can cause premature failure, safety hazards, and costly recalls. That is why composite testing and validation are central to modern manufacturing. Testing determines whether a composite material meets required mechanical, thermal, and chemical specifications, while validation ensures that every production batch consistently delivers those properties. This guide explores the fundamentals, methods, standards, and best practices involved in composite testing and validation so manufacturers can safeguard performance and maintain regulatory compliance.

Understanding Composite Testing in Depth

Composite testing is a comprehensive evaluation process that measures how a composite behaves under various conditions to predict its real-world performance. It typically includes mechanical, thermal, chemical, and environmental assessments. Mechanical tests such as tensile, compressive, and flexural evaluations reveal how the material responds to stretching, squeezing, or bending forces. These tests determine critical values like ultimate tensile strength, elastic modulus, and fatigue life—data that engineers need to design safe structures ranging from aircraft fuselages to high-performance sports equipment.

Thermal testing examines heat resistance and thermal expansion, crucial for aerospace parts that must endure extreme temperature cycles. Chemical and microstructural analysis checks the curing quality of resins, fiber orientation, and the presence of voids or impurities that can compromise performance. Non-destructive testing (NDT) methods, including ultrasonic inspection, infrared thermography, and X-ray computed tomography, allow technicians to locate hidden flaws like delamination or porosity without damaging the sample.

By combining these methods, manufacturers obtain a full picture of a composite’s durability, reliability, and suitability for its intended application. Importantly, composite testing is not a one-time event; it should occur during R&D, prototype development, and full-scale production. Early and continuous testing helps detect problems before they escalate, reduces costly rework, and supports faster product development cycles.

The Crucial Role of Validation in Modern Manufacturing

While testing measures material properties, validation ensures that the entire production process consistently produces composites that meet those properties every time. Validation begins with a detailed design review where engineers define performance goals and tolerances. Next, material qualification confirms that the chosen fibers, resins, and lay-up techniques can achieve those goals under controlled conditions. Process validation then evaluates whether manufacturing steps—such as lay-up, curing, and machining—are repeatable across different production runs.

For example, aerospace manufacturers must demonstrate that autoclave curing yields uniform resin distribution and fiber alignment across multiple batches. Validation often includes pilot production runs, statistical process control, and prototype testing under simulated service conditions like temperature extremes, vibration, or chemical exposure. Documentation is critical: regulators and customers require detailed records of every procedure, test result, and quality checkpoint to confirm compliance with international standards such as ASTM, ISO, FAA, or EASA.

Effective validation offers tangible benefits. It minimizes variability, reduces scrap rates, and ensures that scaling from prototype to mass production does not compromise quality. It also provides assurance to end users—whether airlines, carmakers, or energy companies—that every component delivered meets the same high standards. In industries where a single defect can have catastrophic consequences, robust validation is as essential as the testing itself.

Key Composite Testing Methods and Their Applications

Composite testing employs multiple specialized methods, each targeting different performance aspects:

Mechanical Testing (300+ words)

Mechanical testing evaluates how a composite responds to physical forces. Tensile tests stretch a specimen until it breaks, measuring ultimate strength and elongation. Compression tests apply axial loads to determine buckling resistance, while flexural tests assess bending behavior. Fatigue testing subjects samples to repeated stress cycles, revealing how they endure long-term operational loads such as wind turbine blade rotation or aircraft wing flexing. Impact testing measures energy absorption when struck suddenly—vital for automotive crash components and protective sports gear.

Each of these tests provides engineers with precise numerical data like stress–strain curves, modulus of elasticity, and fatigue limits. By analyzing these results, designers can optimize fiber orientation, resin content, and laminate thickness for specific applications. For example, a racing bicycle frame may prioritize high tensile strength and low weight, while a marine hull might need greater flexural toughness and fatigue resistance. Integrating mechanical testing at multiple production stages—from raw fiber rolls to finished parts—helps catch inconsistencies early and reduces the risk of in-service failures.

Thermal & Environmental Testing (300+ words)

Composites often operate in harsh environments. Thermal testing measures how materials perform when exposed to extreme temperatures or rapid temperature changes. Techniques such as differential scanning calorimetry (DSC) determine glass transition temperature (Tg), while thermogravimetric analysis (TGA) measures weight loss due to decomposition. Coefficient of thermal expansion (CTE) tests identify dimensional changes that could lead to cracking or delamination in aerospace or electronics applications.

Environmental testing subjects composites to moisture, UV radiation, salt spray, and chemical agents to simulate real-world service conditions. For example, marine composites undergo accelerated weathering to evaluate resistance to water absorption and salt corrosion. Fire and flammability tests, such as ASTM E1354 cone calorimetry, assess ignition resistance and smoke production—critical for aviation, rail, and building materials. These evaluations ensure that a composite can withstand decades of service without significant degradation. Combining thermal and environmental testing provides a clear understanding of long-term performance and helps manufacturers meet safety regulations worldwide.

Non-Destructive Testing (NDT) and Chemical Analysis (300+ words)

NDT techniques allow inspection of internal structures without cutting or damaging the material. Ultrasonic testing sends high-frequency sound waves through the composite to detect voids, delaminations, or inclusions. X-ray radiography and computed tomography (CT) scanning create detailed cross-sectional images, revealing fiber alignment and resin distribution. Infrared thermography identifies areas with inconsistent curing or trapped moisture. These methods are indispensable for large, high-value components like aircraft wings or wind turbine blades, where destructive sampling is impractical.

Chemical and microstructural analysis complements NDT by verifying resin chemistry, fiber content, and curing completeness. Spectroscopic techniques such as Fourier transform infrared (FTIR) analysis confirm polymer composition, while scanning electron microscopy (SEM) reveals microscopic defects and fiber–matrix bonding quality. Together, NDT and chemical testing provide a comprehensive, non-invasive evaluation that supports ongoing quality control during production and maintenance.

Industry Standards, Certifications, and Best Practices

Adherence to recognized standards enhances credibility and market access. Key guidelines include ASTM D3039/D3039M for tensile properties, ISO 14125 for flexural properties, and NADCAP accreditation for aerospace suppliers. Following these protocols not only satisfies regulators but also reassures customers about product consistency.

Manufacturers should integrate testing and validation at every stage: design, material selection, prototype fabrication, and full-scale production. Partnering with accredited third-party labs ensures impartial results and simplifies certification audits. Maintaining meticulous documentation—test reports, calibration records, and process logs—is essential for traceability and regulatory compliance. By combining rigorous standards with advanced testing technology, companies can reduce defects, protect end users, and build a reputation for reliability in competitive markets.

Conclusion

Composite testing and validation form the backbone of modern manufacturing for aerospace, automotive, energy, and marine industries. By thoroughly evaluating mechanical, thermal, environmental, and chemical properties—and validating the entire production process—manufacturers can guarantee that every component meets demanding performance and safety requirements. Embracing emerging trends such as automated NDT, digital twin simulations, and sustainability metrics will further strengthen quality assurance and keep companies competitive. In an era where lightweight, high-strength materials define innovation, comprehensive composite testing and validation are not optional—they are essential for long-term success.